Diamond tools store is where quality meets precision for professionals and enthusiasts seeking top-tier cutting, grinding, and polishing solutions. Whether you’re working on large construction projects or intricate glasswork, stepping into a diamond tools store opens up a world of expertly crafted tools designed to tackle even the toughest materials.

These specialized stores cater to a diverse range of customers, from contractors and fabricators to DIY hobbyists, by offering a thoughtfully curated selection of diamond blades, drill bits, grinding wheels, and polishing pads. With knowledgeable staff, organized displays, and a focus on customer education, diamond tools stores have become an essential resource for those who demand both performance and reliability in their work.

Introduction to Diamond Tools Stores

Diamond tools stores are specialized retail outlets or online platforms that focus on supplying diamond-embedded equipment, such as cutting, grinding, drilling, and polishing tools. These stores are essential resources for professionals and hobbyists working with hard and abrasive materials, since diamond tools offer superior performance, durability, and precision compared to conventional alternatives.

Customers who frequent diamond tools stores are typically industry experts, such as contractors in construction, specialists in stone and tile fabrication, glassworkers, manufacturers, and even artists or DIY enthusiasts. Each customer group relies on tailored tool solutions to meet the specific requirements of their projects, whether it involves intricate detailing or large-scale production.

The significance of specialized diamond tool stores lies in their ability to provide expert guidance, high-quality products, and an extensive selection tailored to the unique applications of diverse industries. By focusing solely on diamond-based solutions, these stores offer not only products but also technical expertise, helping professionals achieve optimal results in their work.

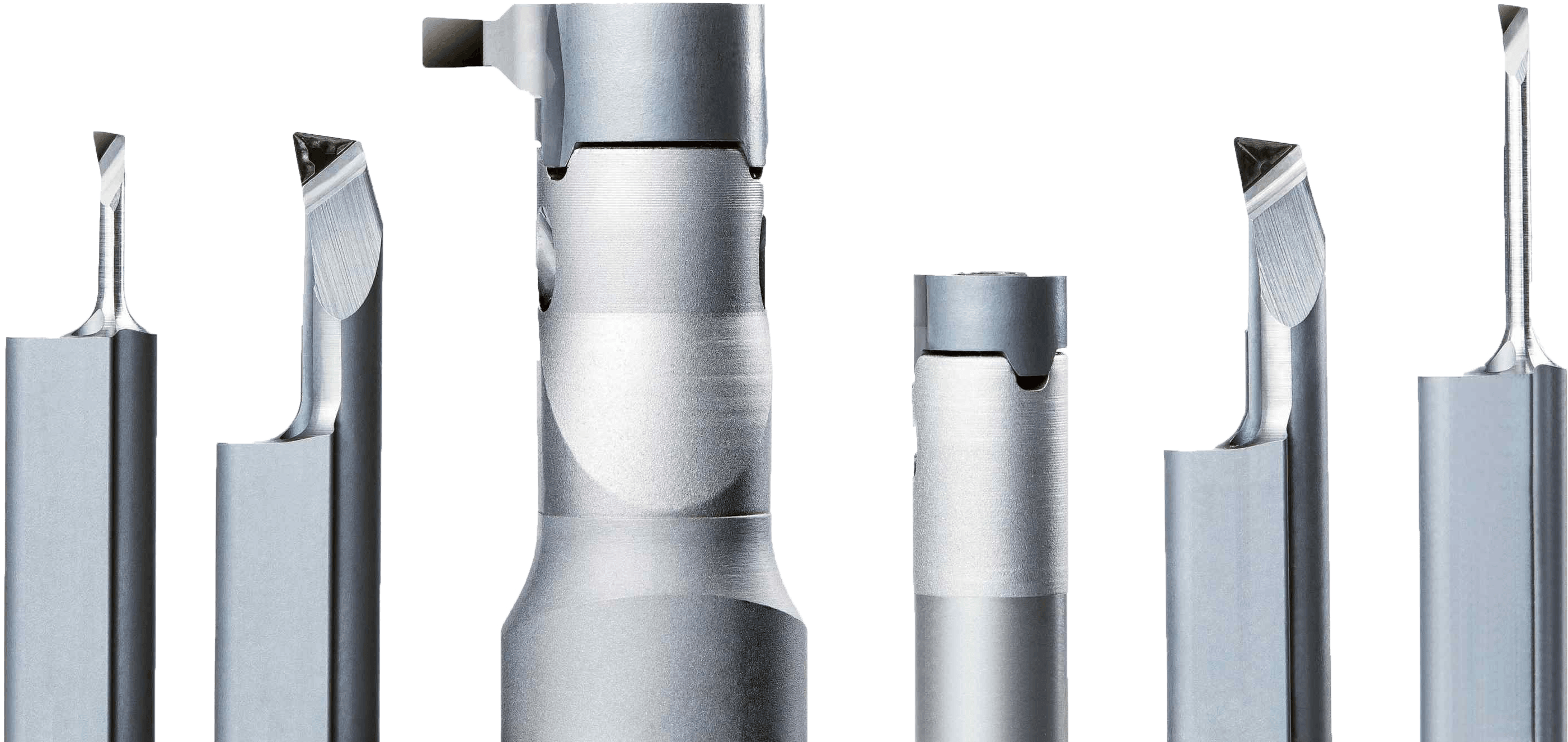

Types of Diamond Tools Available

The range of diamond tools available in these stores is broad, catering to various tasks and materials. Here is a structured overview of common categories:

| Tool Type | Description | Common Uses | Material Compatibility |

|---|---|---|---|

| Diamond Blades | Thin, circular saw blades embedded with diamond grit | Cutting stone, concrete, ceramics, glass | Granite, marble, porcelain, reinforced concrete |

| Diamond Drill Bits | Cylinder-shaped bits with diamond coating | Drilling holes in tile, glass, stone, and concrete | Tile, glass, stone, masonry |

| Diamond Grinding Wheels | Rotary wheels with diamond abrasive segments | Surface grinding, smoothing, shaping materials | Ceramic, stone, carbide, composites |

| Diamond Polishing Pads | Flexible pads with resin-bonded diamond particles | Polishing surfaces to a high shine or smooth finish | Granite, marble, engineered stone, concrete |

For more specialized applications, stores often carry niche diamond tools such as:

- Core drills for large-diameter holes in reinforced concrete

- Profile wheels for shaping decorative stone edges

- Wire saws for block cutting in quarrying

- Electroplated diamond files for fine detail work

Each tool type features unique benefits. For example, diamond blades cut cleaner and faster with less chipping, while diamond drill bits offer longer lifespans and exceptional accuracy when compared to carbide alternatives.

Major Applications and Industries Served: Diamond Tools Store

Diamond tools find their way into a wide span of industries, thanks to their unbeatable efficiency for working with robust materials. Their precision and longevity are especially valued in sectors where quality and speed are non-negotiable.

Prominent industries utilizing diamond tools include:

- Construction – Used for concrete cutting, masonry drilling, and surface preparation.

- Stone Fabrication – Essential for countertop manufacturing, monument building, and decorative stonework.

- Glass Processing – Applied in glass cutting, shaping, and drilling for windows, panels, and art pieces.

- Manufacturing and Automotive – Necessary for tool sharpening, part shaping, and precision grinding.

In each of these fields, diamond tools play crucial roles in everyday procedures:

- Cutting and resizing construction materials for building sites

- Shaping and polishing granite or marble slabs

- Drilling precise holes in fragile glass for architectural installations

- Grinding hard metals and composites in industrial production lines

The use of diamond tools greatly enhances productivity and finish quality by minimizing material wastage and reducing the time required for complex tasks.

Efficiency and Precision Benefits, Diamond tools store

The integration of diamond tools into industry workflows results in higher efficiency and greater precision. With their remarkable hardness, diamond-embedded options maintain sharpness longer and require fewer replacements, while also delivering smoother finishes, tighter tolerances, and less user fatigue. These benefits are especially critical in high-volume or high-value applications.

Selecting the Right Diamond Tool

Choosing the appropriate diamond tool is essential for performance, safety, and cost-effectiveness. The selection process involves understanding the material to be worked on, the project’s requirements, and the technical specifications of available tools.

| Material | Recommended Tool | Grit Size | Application Tips |

|---|---|---|---|

| Granite | Segmented diamond blade | Medium (40-80 grit) | Use wet cutting to reduce dust and blade wear |

| Glass | Continuous rim diamond blade | Fine (100-200 grit) | Light pressure prevents cracks and chips |

| Concrete | Turbo diamond blade | Coarse (30-40 grit) | Ensure adequate cooling and debris removal |

| Ceramic Tile | Diamond drill bit | Medium-Fine (60-100 grit) | Start drilling at an angle for smooth entry |

When choosing between different brands and product lines, consider:

- Reputation and reliability of the manufacturer

- Warranty and available after-sales support

- Compatibility with existing equipment

- Cost-efficiency based on expected lifespan and job requirements

A practical step-by-step procedure for selecting the best tool includes:

- Identify the type of material and its hardness.

- Define the end result (cutting, grinding, polishing, etc.).

- Check the tool’s size, grit, and compatibility with your equipment.

- Evaluate the product’s reviews and brand reputation.

- Consult in-store experts for additional guidance if unsure.

Outcome Summary

In summary, choosing a diamond tools store means gaining access to specialized products, expert guidance, and the latest advancements in tool technology. Whether you’re searching for the right blade for a complex project or seeking advice on maintenance and safety, these stores provide the support and resources you need to achieve precise, professional results every time you work.

Essential FAQs

What types of materials can diamond tools cut or process?

Diamond tools are designed to cut, grind, or polish extremely hard materials such as stone, concrete, ceramics, glass, and some metals.

Do diamond tools work with standard power tool machines?

Most diamond tools are compatible with standard machines like angle grinders, drills, and saws, but always check the tool specifications for proper fitting.

How can I tell when a diamond blade or bit needs replacing?

If you notice reduced cutting efficiency, visible wear on the segments, or increased vibration, it’s likely time to replace the tool.

Are there safety precautions for using diamond tools?

Yes, always wear protective gear such as goggles, gloves, and dust masks. Follow all manufacturer guidelines and ensure proper tool mounting before use.

Can I purchase diamond tools online from these stores?

Many diamond tools stores offer online catalogs and shipping, making it easy to browse and order tools from anywhere.